|

Hebei Ben Hong New Material Technology Co., LTD

|

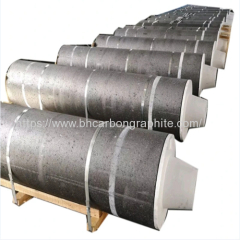

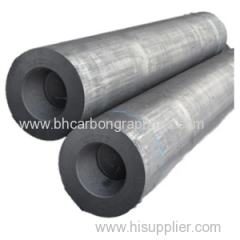

UHP Graphite Electrode for Submerged Electric Furnace

| Price: | 2150.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.arc furnace graphite electrode

2. uhp graphite electrode for eaf

3.rp hp uhp graphite electrode

4.graphite electrode

UHP Graphite Electrode for Submerged Electric Furnace

Product Description

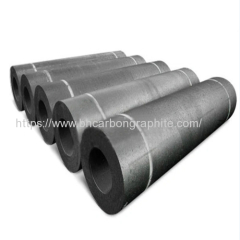

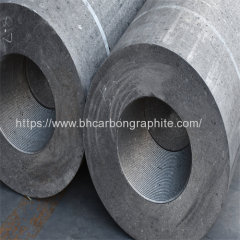

UHP graphite electrode is used for the recycling of steel in the electric arc furnace industry. Its main ingredient is high-value needle bck which is made from either petroleum or coal tar. Graphite electrodes are finished with a cylinder shape and machined with threaded areas at each end. In this way, the graphite electrodes can be assembled into an electrode column using electrode nipple.

In order to meet the requirement of higher work efficiency and lower total cost, large capacity ultra-high power arc furnaces are becoming more and more popular. Because of this, UHP graphite electrodes with diameters of over 500 mm will dominate market.

Specifications | classification | Specific resistance | Bulk density | Transverse strength | C.T.E |

mm | μΩ·m | g/cm³ | MPa | 10-6/℃ | |

UHP 300-400 | Electrode | ≤6.2 | ≥1.67 | ≥10.5 | ≤1.5 |

Nipple | ≤5.3 | ≥1.74 | ≥20.0 | ≤1.3 | |

UHP 450-500 | Electrode | ≤5.8 | ≥1.66 | ≥10.5 | ≤1.4 |

Nipple | ≤4.5 | ≥1.76 | ≥20.0 | ≤1.3 | |

UHP 550-700 | Electrode | ≤5.6 | ≥1.68 | ≥10.0 | ≤1.3 |

Nipple | ≤4.3 | ≥1.78 | ≥22.0 | ≤1.2 |

Our Advantage

Product Line

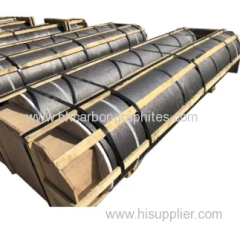

Packaging & Shipping

Packaging & Shipping

Packing with wooden case + pallet + enlace with baling band

Guidance of Using

Being hard and brittle ,artificialgraphite electrode shall be specially handled.Proper operationg may reduce the consumption and cost.

1. Professional tools should be used for hoisting graphite electrodes. It is strictly forbidden to use a crowbar to prevent impact damage during handling.

2. Graphite electrodes are prohibited from rain, snow and water, and should be kept dry. If it is found to be damp, it should be dried before use, the temperature should not exceed 100 ºC, and the drying time should not be less than 48h.

3. Do not stack near debris such as clay, slag, etc., so as not to pollute the surface of the graphite electrode and affect the conductive effect.

4. Before the graphite electrode is connected, carefully check whether the electrode connector hole is intact, whether the connector thread is damaged, and whether the connector bolt is lost. When the electrode is lifted, the electrode connector thread of the ground terminal should be prevented from being damaged.

5. Dust and debris in the joints and joint holes should be blown dry with compressed air.

6. Graphite electrodes must be tightly connected, and no tilt is allowed during connection. Torque wrenches should be used to prevent excessive force or too small, and the gap is not greater than 0.4mm.

7. The electrode holder should be clamped, not loose and in good contact, and no arc should be generated. Otherwise, the connection will be reddish, oxidized, thinned and broken. eaf graphite electrodes

8. If the electrode is lifted with a metal lifting plug, the thread in the joint hole must not be damaged. After lifting, the lifting plug should be unscrewed to prevent dust and debris from falling into the joint hole.

9. When the electrode lifting device of the electric furnace is running, it should be kept stable. After the furnace cover is repaired, check whether the furnace cover is positioned correctly. During smelting, refractory materials are used to close the furnace lid to prevent the oxidation of the upper electrode of the flame in the furnace. electric arc furnace graphite electrodes

10. The holder should be clamped outside the safety wire of the electrode connector hole area.

11. When distributing the molten pool, the big piece is at the bottom and the small piece is at the top. Do not place the charge with poor conductivity on the top. During melting, the unmelted charge should be handled in time to prevent the collapsed material from breaking the electrode.

FAQ

1. Are you Factory or Trading?

We are factory with ISO 9001 certified

2. How about the Capacity?

High output, with an annual output of 80,000 tons, timely delivery; guarantee delivery date.

3. What can we buy from you?

Graphite electrode,electrode paste,carbon raiser,carbon product, and other graphite products.

4. How to confirm the grade of graphite electrode?

Please send inquiry to us, our sales manager will confirm the details and price for you. electric arc furnace electrode

Customers will be asked to provide electric arc furnace parameters and specifications and sizes of electrode.

5. What is your payment service?

Accepted Delivery Terms: FOB, CFR, CIF, EXW;

Accepted Payment Currency: USD, EUR, CNY;

Accepted Payment Type: T/T, L/C,CAD;