|

Hebei Ben Hong New Material Technology Co., LTD

|

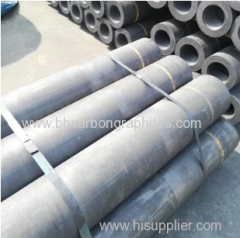

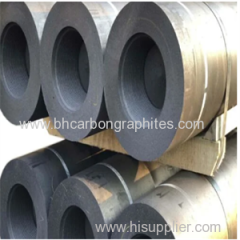

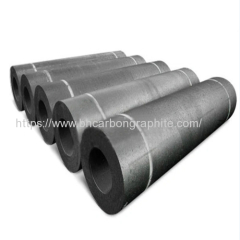

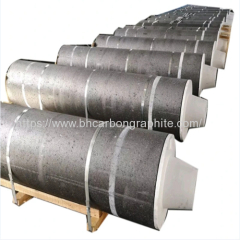

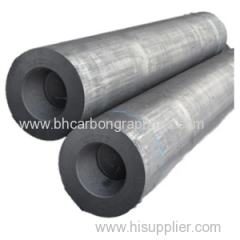

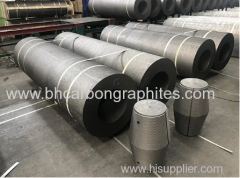

High Quaity 500*2400 UHP Graphite Electrode for Eaf/Lf

| Price: | 2500.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Application

1. Electric arc steelmaking furnace.

2. Ladle arc refining furnace.

3. Ore-heating furnaces.

4. Resistance furnaces

Product Description

Graphite Electrodes are a high-temperature resistant graphite conductive refractory material used in the metallurgical industry. RP Graphite Electrodes are made of Petrolum bck, bituminous bck as aggregates, coal tar pitch as binders, after raw material calcination, crushing and milling, batching, kneading, molding, roasting, impregnation, graphitization, and machining, which are also known as artificial graphite electrodes in order to distinguish from natural graphite electrodes made of natural graphite.

Details:

Cautions:

> Be careful when transporting and pilling electrodes with a forklift and avoid a collision. One layer of goods at a time; notice the balance and alignment and avoid falling or breakage.

> When loading and unloading with a forklift, wire rope must be used and steel wrapping tape cannot be employed directly to fetch electrodes.

> Electrode should be stored in a clean and dry place. When pilling up outdoors, it should be covered with rain-proof tarpaulin and the number of piling layers ought not to exceed four.

> When using electrodes, special tools should be employed to cut the steel wrapping tape, and crane should not be adopted to avoid bursting.

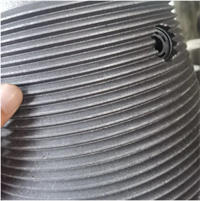

> Steel-wire ball, metallic brush, or emery cloth is not allowed for cleaning the electrode thread, but compressed air free of oil and water is available.

> Use revolved resilient hanger and put a soft truss pad under the electrode joint to avoid breakage of the thread.

> Lift the electrode to the furnace by using a hoister with resilient hangers, and find out the center and move slowly downwards, screw and tighten with a hoop.

> If the two poles of the two electrodes are untouched or touched in overpressure, this may cause a bad effect.

> In order to avoid electrode breakage put the large materials in the lower part and small materials in the upper part.

Product Parameters

RP Graphite Electrodes 350mm

| Project | Diameter(mm) | ||

| RP250mm | |||

| Electrode | Nipple | ||

| Resistivity≤ | (μΩ.m) | 8.0 | 5.5 |

| Bending Strength≥ | Mpa | 10.0 | 15.0 |

| Elastic Modulus≤ | Gpa | 9.3 | 14.0 |

| Bulk Density≥ | g/cm3 | 1.63 | 1.75 |

| C.T.E(*10-6/ºC) ≤room temperature~600ºC | 10-6/ºC | 2.9 | 2.7 |

| Ash≤ | % | 0.3 | 0.3 |

Allow Capacitance Flow of the graphite electrod

| Nominal Diameter | Allowable capacitance flow(A) | Electrice current density | |

| Milimeter | Inch | ||

| 350 | 14'' | 13500-18000 | 14-18 |

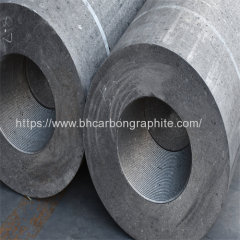

Nipple Size of 350mm RP Graphite Electrode

| Diameter | IEC Code | Diameter 1 | length | Diameter 2 |

| 350mm | 203T4N | 203.20mm | 254.00mm | 148.20mm |

Packaging & Shipping

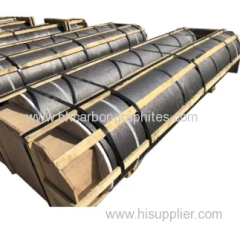

We pack the graphite electrode with plastic wrapping keeping the graphite electrodes dry and with foam board and wooden board outside avoid breakage.

After Sales Service

1. The warranty period of all products sold by our factory is one year. During the warranty period, door-to-door repairs are free (except for malfunctions or damage caused by human factors or irresistible natural phenomena).

2. After receiving the notice of repair, rush to the scene and solve the problem within seven working days.

3. Users can consult related technical issues through after-sales telephone calls and provide clear solutions.

4. Productively cooperate with users to do a good job of on-site operation and maintenance management of products, and can provide users with spare parts and accessories of our products at cost prices at any time.

5. When the user has a performance failure during normal use, the company has the above warranty service. In addition, if applicable laws and regulations provide otherwise, the company will comply with relevant laws and regulations.

6. During the warranty period, paid maintenance services will be implemented in the following situations:

(1) Damage due to man-made or irresistible natural phenomena;

(2) Failure or damage caused by improper operation;

(3) Failure or damage due to the transformation, decomposition, and assembly of the product.

FAQ

Q: What information should I let you know if i want to get a quotation?

A: The required material dimension (diameter*length; if possible, please kindly supply us drawings).

If it is possible, please also provide the application of products, we will recommend the most suitable products with details for confirmation.

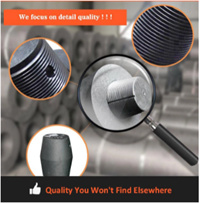

Q: How can you control your quality?

A: For each production processing, We have a complete QC system for the chemical composition and physical properties. After production, all the goods will be tested, and the quality certificate will be shipped along with goods.

Q: What is your lead time?

A: It usually needs about 15- 20 days after receiving the PO.

Q: What are your payment terms?

A: We can accept a 30% deposit, 70% balance to be against the BL copy or by LC, or other payment terms. (according to your order value)

Q: Can we visit your company?

A: Yes, for sure, It's my pleasure to visit Our company.

Q: What is the shipping cost?

A: The shipping cost is determined by the destination port, weight, packing size, total CBM of the products, we will try best to get the most reasonable shipping cost from the forwarders or express couriers to help you save more money.