|

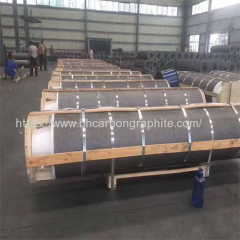

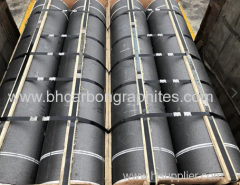

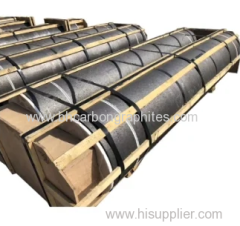

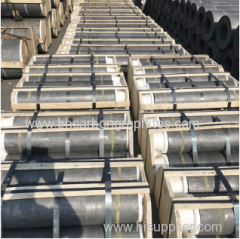

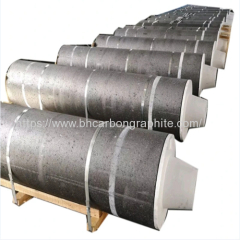

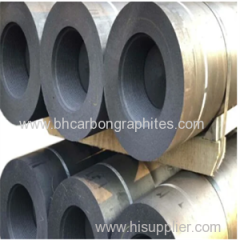

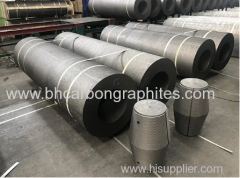

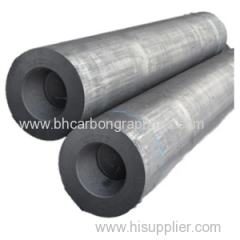

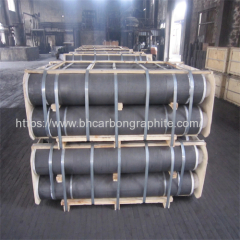

Hebei Ben Hong New Material Technology Co., LTD

|

Gold Index: 41711

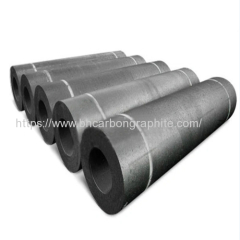

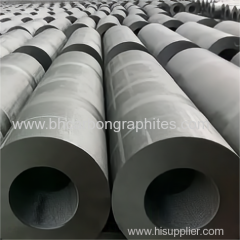

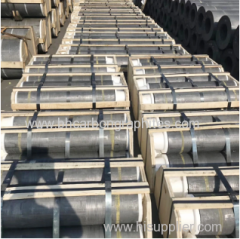

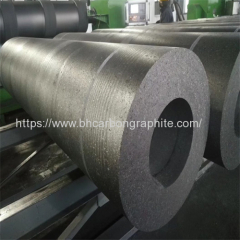

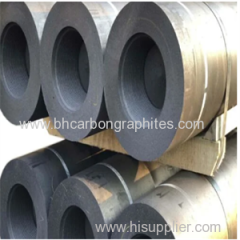

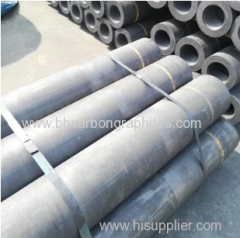

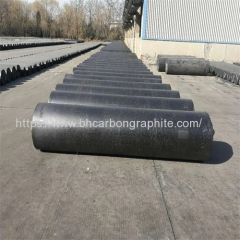

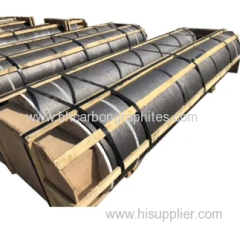

Ultra high power Graphite Electrode 400mm

| Price: | 3000.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Product has low resistivity, good electrical conductivity, low ash content, compact structure, good oxidation resistance, high mechanical strength .

Size of Electrodes:

| Norminal Diameter (mm) | Actual Diameter (mm) | Length (mm)* | ||||

| mm | inch | Max | Min | Low Spot | ||

| 75 | 3 | 78 | 73 | 72 | 1600 | |

| 100 | 4 | 103 | 98 | 97 | 1600 | |

| 130 | 5 | 132 | 127 | 126 | 1600 | |

| 150 | 6 | 154 | 149 | 146 | 1800 | |

| 200 | 8 | 205 | 200 | 197 | 1800 | |

| 225 | 9 | 230 | 225 | 222 | 1800 | |

| 250 | 10 | 256 | 251 | 248 | 1800 | |

| 300 | 12 | 307 | 302 | 299 | 1800 | |

| 350 | 14 | 357 | 352 | 349 | 1800 | |

| 400 | 16 | 409 | 403 | 400 | 1800.2100 | |

| 450 | 18 | 460 | 454 | 451 | 1800.2100 | |

| 500 | 20 | 511 | 505 | 502 | 1800.2100 | |

| 550 | 22 | 562 | 556 | 553 | 2100.2400 | |

| 600 | 24 | 613 | 607 | 604 | 2100.2400 | |

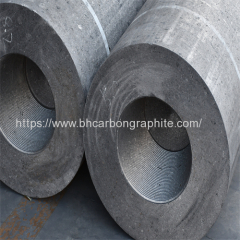

Dimension of Cylinder Nipples:

| Norminal Diameter (mm) | Size of Nipples (mm) | Size of Sockets (mm) | Thread (mm) | ||||||||||||||

| mm | inch | D | d | L | D | d | H | a | b | c | |||||||

| 75 | 3 | 41.2 | 0 -0.5 | 33.8 | 0 -0.5 | 103.0 | 0 -1.0 | 42.5 | +0.50 | 35.1 | +0.50 | 53.0 | +7 0 | 8.47 | 2.37 | 2.82 | |

| 100 | 4 | 66.7 | 59.3 | 135.0 | 68.0 | 60.6 | 69.0 | ||||||||||

| 130 | 5 | 69.8 | 62.4 | 153.0 | 71.1 | 63.7 | 78.0 | ||||||||||

| 150 | 6 | 88.9 | 81.5 | 169.0 | 90.2 | 82.8 | 85.0 | ||||||||||

| 200 | 8 | 122.2 | 114.8 | 203.0 | 123.5 | 116.1 | 103.0 | ||||||||||

| 225 | 9 | 139.7 | 128.8 | 203.0 | 140.98 | 130.0 | 106.0 | 12.70 | 3.67 | 4.32 | |||||||

| 250 | 10 | 152.4 | 141.5 | 228.0 | 154.1 | 143.2 | 116.0 | ||||||||||

| 300 | 12 | 184.2 | 173.3 | 254.0 | 185.9 | 175.0 | 129.0 | ||||||||||

| 350 | 14 | 215.9 | 205.0 | 280.0 | 217.6 | 206.7 | 142.0 | ||||||||||

| 400 | 16 | 244.5 | 233.6 | 305.0 | 246.2 | 235.3 | 155.0 | ||||||||||

| 450 | 18 | 274.3 | 0 -0.7 | 263.4 | 0 -0.7 | 340.0 | 0 -2 .0 | 276.0 | +0.70 | 265.1 | +0.70 | 172.5 | |||||

| 500 | 20 | 296.0 | 285.1 | 375.0 | 297.7 | 286.8 | 190.0 | ||||||||||

Dimension of 3TPI Conical Nipples:

| Norminal Diameter (mm) | Size of Nipples (mm) | Size of Sockets (mm) | Thread (mm) | ||||||||||

| mm | inch | D | L | d | 1 | d | H | ||||||

| 225 | 9 | 139.7 | 0 -0.5 | 203.2 | 0-1 | 90.73 | 0 -5 | <10 | 131.27 | +0.5 0 | 107.6 | +7 0 | 8.47 |

| 250 | 10 | 155.57 | 220.10 | 103.80 | 147.14 | 116.00 | |||||||

| 300 | 12 | 177.17 | 270.90 | 116.90 | 168.73 | 141.50 | |||||||

| 350 | 14 | 215.90 | 304.80 | 150.00 | 207.47 | 158.40 | |||||||

| 400 | 16 | 215.9 | 304.8 | 150 | 207.47 | 158.40 | |||||||

| 400 | 16 | 241.30 | 338.70 | 169.80 | 232.87 | 175.30 | |||||||

| 450 | 18 | 241.30 | 338.70 | 169.80 | 232.87 | 175.30 | |||||||

| 450 | 18 | 273.05 | 355.60 | 198.70 | 264.62 | 183.80 | |||||||

| 500 | 20 | 273.05 | 355.60 | 198.70 | 264.62 | 183.80 | |||||||

| 500 | 20 | 298.45 | 372.60 | 221.30 | 290.02 | 192.20 | |||||||

Dimension of 4TPI Conical Nipples:

| Norminal Diameter (mm) | Size of Nipples (mm) | Size of Sockets (mm) | Thread (mm) | ||||||||||

| mm | inch | D | L | d | 1 | d | H | ||||||

| 75 | 3 | 46.04 | 0 -0.5 | 76.20 | 0 -1 | 20.80 | 0 -5 | <7 | 39.72 | +0.5 0 | 44.10 | +7 0 | 6.35 |

| 100 | 4 | 69.85 | 101.60 | 40.30 | 63.53 | 56.80 | |||||||

| 130 | 5 | 79.38 | 127.00 | 45.60 | 73.06 | 69.50 | |||||||

| 150 | 6 | 92.08 | 139.70 | 56.20 | 85.76 | 75.90 | |||||||

| 200 | 8 | 122.24 | 177.80 | 80.00 | 115.92 | 94.90 | |||||||

| 225 | 9 | 139.70 | 177.80 | 97.46 | 133.38 | 94.90 | |||||||

| 250 | 10 | 152.40 | 190.50 | 108.00 | 146.08 | 101.30 | |||||||

| 300 | 12 | 177.80 | 215.90 | 129.20 | 171.48 | 114.00 | |||||||

| 350 | 14 | 203.20 | 254.00 | 148.20 | 196.88 | 133.00 | |||||||

| 400 | 16 | 222.25 | 304.80 | 158.80 | 215.93 | 158.40 | |||||||

| 400 | 16 | 222.25 | 355.60 | 150.00 | 215.93 | 183.80 | |||||||

| 450 | 18 | 241.30 | 304.80 | 177.90 | 234.98 | 158.40 | |||||||

| 450 | 18 | 241.30 | 355.60 | 169.42 | 234.98 | 183.80 | |||||||

| 500 | 20 | 269.88 | 355.60 | 198.00 | 263.56 | 183.80 | |||||||

| 500 | 20 | 269.88 | 457.20 | 181.08 | 263.56 | 234.60 | |||||||

| 550 | 22 | 298.45 | 355.60 | 226.58 | 292.13 | 183.80 | |||||||

| 550 | 22 | 298.45 | 457.20 | 209.65 | 292.13 | 234.60 | |||||||

| 600 | 24 | 317.50 | 355.60 | 245.63 | 311.18 | 183.30 | |||||||

| 600 | 24 | 317.50 | 457.20 | 228.70 | 311.18 | 234.60 | |||||||

RP Specifications:

| Item | Unit | Norminal Diameter(mm) | ||||

| 75~130 | 150~225 | 250~300 | 350~500 | |||

| Electric Resistivity Max | Electrode | μΩ·m | 8.5 | 9.0 | 9.0 | 9.0 |

| Nipples | 6.5 | 6.5 | 6.5 | 6.5 | ||

| Flexural Strength Min | Electrode | MPa | 9.8 | 9.8 | 7.8 | 6.4 |

| Nipples | 13.0 | 13.0 | 13.0 | 13.0 | ||

| Elastic Modulus Max | Electrode | GPa | 9.3 | 9.3 | 9.3 | 9.3 |

| Nipples | 14.0 | 14.0 | 14.0 | 14.0 | ||

| Bulk Density Min | Electrode | g/cm³ | 1.58 | 1.52 | 1.52 | 1.52 |

| Nipples | 1.68 | 1.68 | 1.68 | 1.68 | ||

| C.T.E. Max(100ºC~600ºC) | Electrode | 10¯6 /ºC | 2.9 | 2.9 | 2.9 | 2.9 |

| Nipples | 2.7 | 2.7 | 2.8 | 2.8 | ||

| Ash Max | % | 0.5 | 0.5 | 0.5 | 0.5 | |

HP Specifications:

| Item | Unit | Norminal Diameter(mm) | |||

| 200~400 | 450~500 | 550~600 | |||

| Electric Resistivity Max | Electrode | μΩ·m | 6.8 | 7.5 | 7.0 |

| Nipples | 5.5 | 5.5 | 5.0 | ||

| Flexural Strength Min | Electrode | MPa | 10.5 | 9.8 | 10.0 |

| Nipples | 14.0 | 14.0 | 16.0 | ||

| Elastic Modulus Max | Electrode | GPa | 12.0 | 12.0 | 12.0 |

| Nipples | 16.0 | 16.0 | 18.0 | ||

| Bulk Density Min | Electrode | g/cm³ | 1.60 | 1.60 | 1.65 |

| Nipples | 1.70 | 1.70 | 1.75 | ||

| C.T.E. Max(100ºC~600ºC) | Electrode | 10¯6 /ºC | 2.4 | 2.4 | 2.4 |

| Nipples | 2.2 | 2.2 | 2.2 | ||

| Ash Max | % | 0.3 | 0.3 | 0.3 | |

UHP Specifications:

| Item | Unit | Norminal Diameter(mm) | |||

| 300~400 | 450~500 | 550~600 | |||

| Electric Resistivity Max | Electrode | μΩ·m | 6.2 | 6.3 | 5.8 |

| Nipples | 4.5 | 4.5 | 4.0 | ||

| Flexural Strength Min | Electrode | MPa | 11.5 | 11.5 | 11.0 |

| Nipples | 20.0 | 20.0 | 22.0 | ||

| Elastic Modulus Max | Electrode | GPa | 14.0 | 14.0 | 14.0 |

| Nipples | 20.0 | 20.0 | 22.0 | ||

| Bulk Density Min | Electrode | g/cm³ | 1.71 | 1.70 | 1.68 |

| Nipples | 1.76 | 1.78 | 1.80 | ||

| C.T.E. Max(100ºC~600ºC) | Electrode | 10¯6 /ºC | 1.5 | 1.5 | 1.5 |

| Nipples | 1.4 | 1.4 | 1.3 | ||

| Ash Max | % | 0.3 | 0.3 | 0.3 | |

Current-Carrying Capacity of RP graphite electrodes

| Norminal diameter(mm) | Current-Carrying Capacity(A) | Current Density(A/cm²) |

| 75 | 1000~1400 | 22-31 |

| 100 | 1500~2400 | 19-30 |

| 130 | 2200~3400 | 17~26 |

| 150 | 3000~4500 | 16-25 |

| 200 | 5000~6900 | 15-21 |

| 250 | 7000~10000 | 14-20 |

| 300 | 10000~13000 | 14~18 |

| 350 | 13500~18000 | 14~18 |

| 400 | 18000~23500 | 14~18 |

| 450 | 22000~27000 | 13~17 |

| 500 | 25000~32000 | 13~16 |

| 550 | 30000~42000 | 13~16 |

| 600 | 40000~53000 | 13~16 |

Current-Carrying Capacity of HP graphite electrodes

| Norminal diameter(mm) | Current-Carrying Capacity(A) | Current Density(A/cm²) |

| 200 | 5500~9000 | 18-28 |

| 250 | 8000~13000 | 18-25 |

| 300 | 13000~17400 | 17~24 |

| 350 | 17400~24000 | 17~24 |

| 400 | 21000~31000 | 16~24 |

| 450 | 25000~40000 | 15~24 |

| 500 | 30000~48000 | 15~24 |

| 550 | 44000~58000 | 15~24 |

| 600 | 52000~67000 | 15~24 |

Current-Carrying Capacity of UHP graphite electrodes

| Norminal diameter(mm) | Current-Carrying Capacity(A) | Current Density(A/cm²) |

| 300 | 15000~22000 | 20~30 |

| 350 | 20000~30000 | 20~30 |

| 400 | 25000~40000 | 19~30 |

| 450 | 32000~45000 | 19~27 |

| 500 | 38000~55000 | 18~27 |

| 550 | 45000~70000 | 18~27 |

| 600 | 50000~97000 | 18~27 |

Precautions for use:

1. When selecting electrode diameter for steel making, please refer to electrode current capacity.

2.Graphite electrodes should be protected from rain and snow during transportation and storage. Before use, they must be dried.

3.Graphite electrodes should be handled with care during loading, unloading, and transportation to protect the threads and prevent damage.

4.Before connecting the electrode, the electrode socket thread must be blown out with compressed air, and then the nipples and the electrode should be tightened.

5.The electrode lifting device of the electrode should not shake during operation to prevent the nipples from loosening and tripping.

6.The electrode holder must not hold the electrode near the nipple socket.

7.When charging the furnace, a large steel block should be placed at the lower part to prevent the material from collapsing and breaking the electrode during melting.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

You May Like:

Product (501)

- graphite electrode (494)

- Graphite Electrode Nipple (5)

- Graphite Crucible (2)