|

Hebei Ben Hong New Material Technology Co., LTD

|

Gold Index: 41711

Product (501)

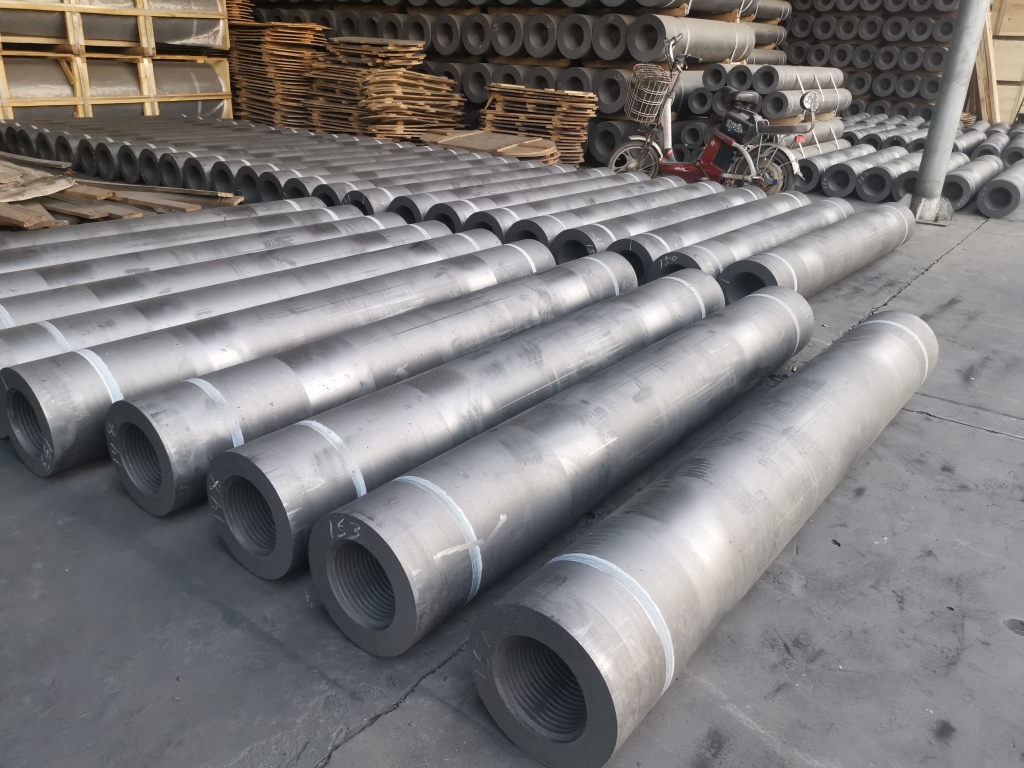

- graphite electrode (494)

- Graphite Electrode Nipple (5)

- Graphite Crucible (2)

News (52)

Credit Report

Products Index

News

How to reduce the loss of graphite electrode at high temperature?

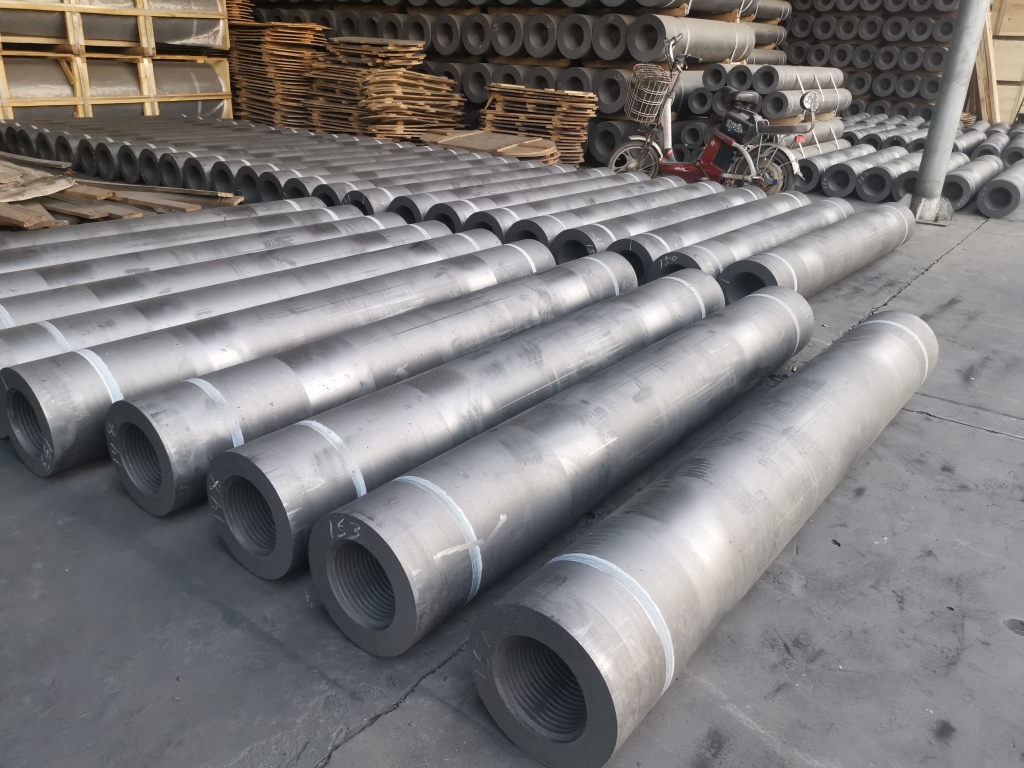

Graphite electrode demand is large, graphite electrode began to oxidize in the air about 600℃, and the temperature of the furnace atmosphere is above 1500℃, the oxidation rate is very fast, data show that when steelmaking, do not do oxidation prevention measures electrode side column oxidation accounts for more than 60% of the electrode consumption, oxidation is an important reason for the increase of electrode consumption. So how do you prevent graphite from oxidizing?

Brush coating RLHY-306 graphite electrode anti-oxidation coating, coating using inorganic nano technology, after material polymerization reaction, high temperature sintering, crushing, grinding of high temperature resistant ceramic coating, graphite electrode anti-oxidation protective agent with nano composite adhesive as film forming agent, adding a variety of nano functional filler material to form a dense anti-oxidation coating.

RLHY-306 graphite electrode anti-oxidation coating can play a very good sealing effect, in the high temperature section, isolate oxygen and graphite, block the reaction of graphite and oxygen at high temperature, reduce the consumption of graphite electrode by more than 30%, coating anti slag erosion and penetration, reduce the inclusion in steel, steel, aluminum water, copper water has a pure effect.

Use RLHY-306 graphite electrode anti-oxidation coating protectant, graphite electrode anti-oxidation coating protectant scope of application: suitable for graphite products such as graphite electrode, anode carbon block, electrolytic aluminum factory, graphite mold, graphite crucible, graphite bearing and other graphite products surface sealing anti-oxidation, sealing anti-corrosion, increase the strength of the material.

1. Matrix treatment

Remove the dust, foreign bodies and other adhesive materials on the surface of the graphite electrode and graphite parts to ensure that the surface of the substrate is dry and clean.

2. Paint mix

Coating in the process of storage and transportation, it is inevitable that precipitation will occur. When used, the coating should be stirred evenly, filtered with a 40-mesh screen, and poured into another container. It is required to stir slowly and continuously to ensure that the paint is always in suspension.

3. Environmental conditions

The ambient temperature of painting operation is generally not less than 10℃, the surface temperature should be more than 3℃ above the dew point, and the relative humidity of the air should not exceed 85%.

Step 4 Paint

Brush, spray, spray; When brushing, it is recommended to brush 2-3 times. When brushing, try to make the substrate surface in a state of infiltration, so as to make the coating penetrate into the graphite parts as far as possible. Contact us for more graphite electrode application guidelines.

Pre Page:

Introduction to graphite powder

Next Page:

What is the difference between...